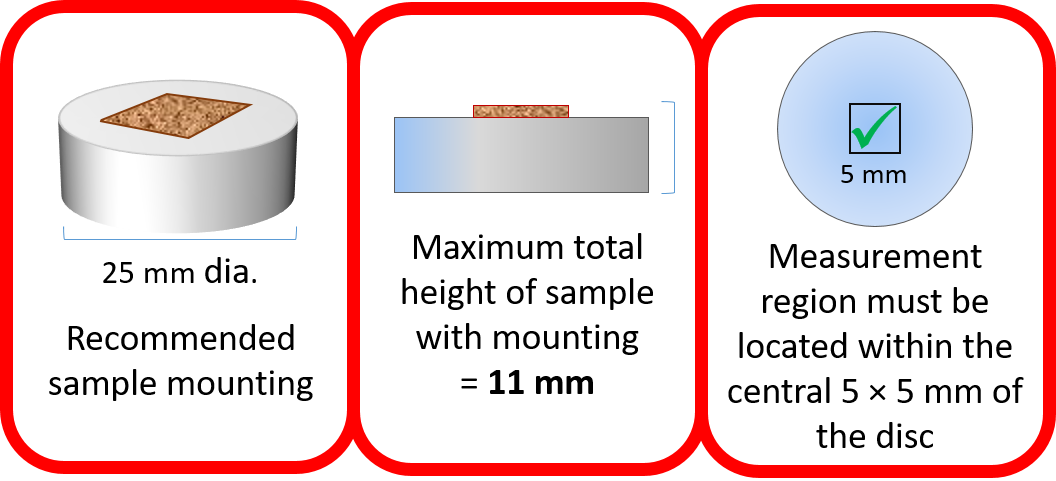

Samples are best mounted on a 25 mm metal disc to ensure correct positioning in the macro-ATR accessory. The sample itself may be mounted on (for example) a glass slide, which can then be mounted on the metal disc with a weak adhesive. The beamline has a number of 25 mm discs of various thicknesses (2 - 10 mm height) available for use during your beamtime, including one heating/cooling mounting disc for temperature controlled studies. (See figure below)

Figure: [Left] 25 mm diameter metal discs for mounting macro-ATR samples. [Right] Temperature controlled macro-ATR sample mounting disc